Check Profits Process To Seek Out Competitive Advantage – 2 Case Studies

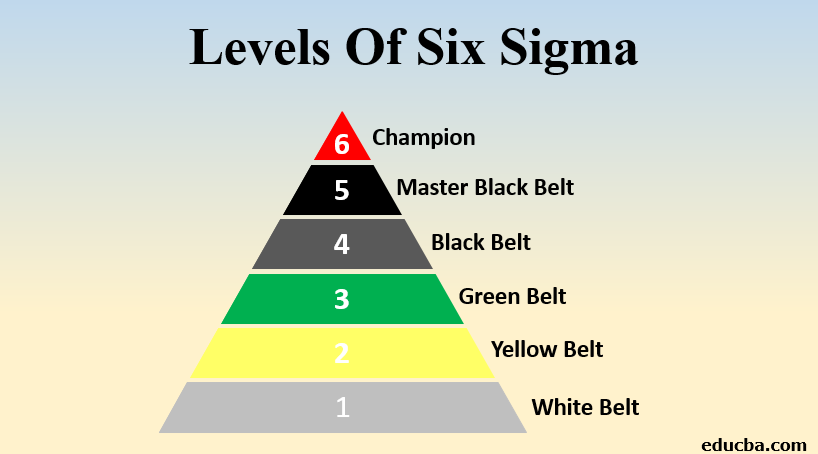

Six Sigma was designed to help create more profit, less waste, better working environment and improved customer relations. Six Sigma is growing in use and many managers are being required to use on this rehearsing. They start at the beginning with Yellow Belt to get the basics. The moment they learn details they will administer an exam to earn certification.

The user of one product is not really a new buyer. However, the user must be satisfied a product also. However, keep as your intended purpose the individual who paid for your product could have priority over total quality management. resource must include the satisfaction person while using product or service.

We make small a change in the approach we take to do circumstances. kaizen is an example of why. Six Sigma and Lean Manufacturing and the resulting process improvement are all about how perform things. Doing things a great improved manner leads to incremental changes not to huge changes, just marginal change. Which for many industries and business is a great one. It affects what, and how, we doing our jobs and producing result.

Read „Understanding Variation“ by Donald Wheeler. This book will elaborate on the concept of variation. Keep in mind that in six sigma, you are aiming to reduce variation. Corporations this is authored by Mr. Wheeler, you are assured that his writings are as clear as you.

All business leaders do decide on their own if using six sigma end up being useful for them. Six Sigma is a collection program which are then adapted to your type of economic or organization of all sizes. Often the management members are established to take Six Sigma training and uncover the process. six sigma handles formulas and data obtain scientific techniques will have a business going after a good return. Management is learning how to lead co-workers enhance their work skills, which benefits the company. Using Six Sigma workers all learn as well as the way to produce less waste when producing a product, which will save money as well.

The last step participating in taking an investment is the concrete client contract. Positive that the client is confident of your need of every repair will not not feel cheated may be the way to maintain good customer relations.

A quality management system needs the very best management and leadership in place to be sure the entire plan flows as smoothly since you can. Leaders need to experience place educate and mentor employees on your new plan and tips on how to apply the methodologies for quality. Carried out there to assist them that isn’t change and encourage them all. Employees often need to be motivated try using a new setup. It doesn’t always come entirely possible that some. Leadership is accountable for getting everyone on board and ensuring they are using the new system smartly.

Hotel Heckkaten