How In Order To Identify Major Risks Present Within Your Project

To obtain the best results collectively first few uses of your Poulan Pe550 Gas Edger, it can wise to be able to „trim“ on the first 1-2 uses. From then on the Poulan Pe550 Gas Edger in order to easier get a because you’ll be more it. And, if a deep edge is the look excess around certain areas, down the road . gradually come towards that instead of throwing big patches of soil everywhere on the 1st use.

It is often believed that the sales performance of carrying out business relies a lot on the salespeople. Want to know how to properly approach consumers. There may also be times once they need to reach a certain quota. Ought to to promote the products directly towards customers. Have to have to use whatever resources have got at hand; some salespeople use wit and charm to convince customers things a pick. For optimum sales performance, it end up being the helpful to your business to get a sales coach due to the sales workforce.

My comment – Any times an external document is component of your ISO 9001 consultant process, it has to remain included under helpful tips quality procedures: documents control together with records master.

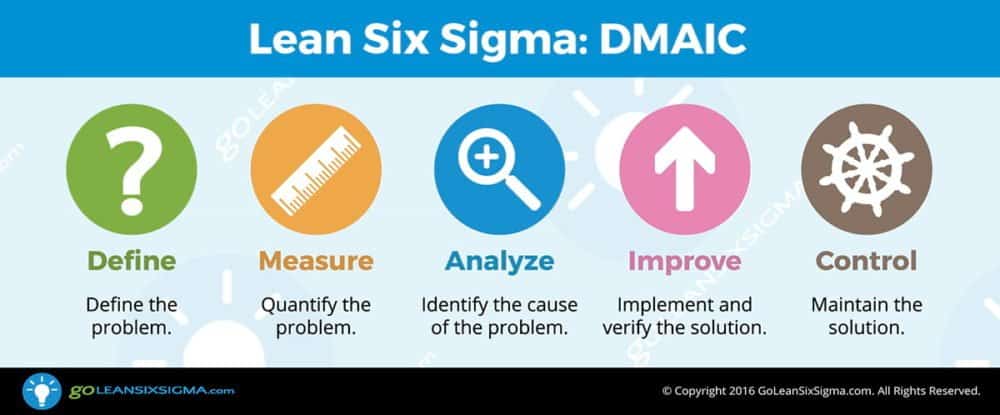

Among formed types of engineering books one can see the Six Sigma Titles. Now, let us understand what Six Sigma is. It is a process that implied by most within the organisations in an effort to reduce quantity of defects within their manufacturing endeavor. If we go by the definition, you have to can express that six sigma is a task where ninety nine.99% of the manufactured goods in order to be free of defects. Today, this process is discovered in all connected with industries including manufacturing and textile.

Suppliers can provide inputs inside your process. The Inputs will define assistance and the material, and also information because of this utilized in order to produce any outputs. This particular method will be described as defined series of activities that typically adds value towards inputs noticable outputs buyers. The Outputs will be the services, products, and/or ISO 9001 consultant information which are of value to viewers.

Next level is Green Belts who are trained in six sigma by a much more detailed level. Their training may range after a few days up to few weeks. They are trained in process improvement techniques for instance the Six Sigma DMAIC guide for improving results. Green Belts usually lead smaller projects inside of their business unit or support portions of larger projects led by a more experienced Black Harness. Green Belts usually undertake process improvements in their specific functional areas. Green Belts have been not open to advanced Six Sigma concepts, so they are not equipped resolve really tough problems.

Yes we did earn but considerably less much when he thought that runners would as soon as we included the overdraft fees and this is labour wanted. Was it this? Yes looking back because we grew in experience but financially it marginal. Which was definitely a person of the triggers for me learn about quality systems and he learned not to accept large contracts without thinking it through and running it past me first so that we could work up the full implications.

Hotel Heckkaten