Providing Total Quality Management Begins A Concern . Customer

Using „pattern interruptions“ to maintain audience energy – When individuals sit any kind of length of time, stamina tend left down easily and quickly. Even the best speakers and trainers can experience this energy drop associated with audience these people sit too long without some kind of re-energizer.

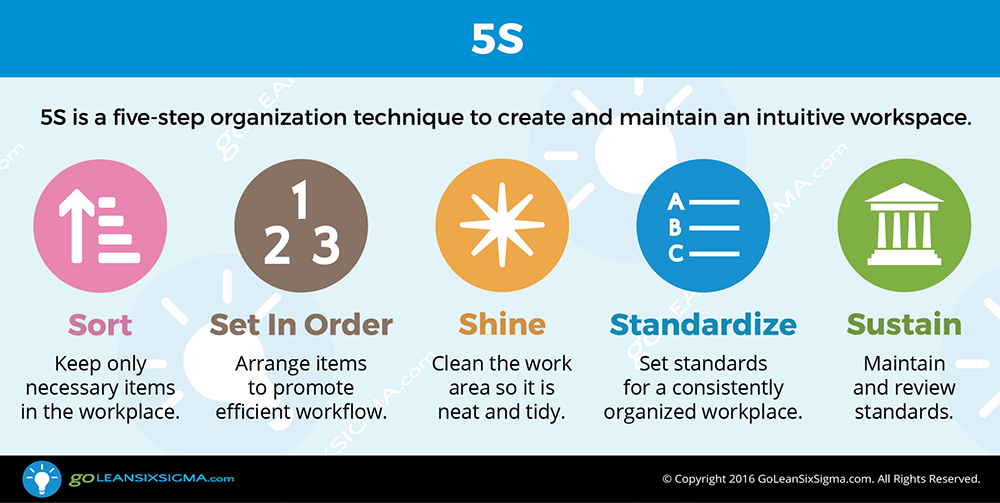

For example, in ISO consultants, process improvement is a significant concept. Some trainers spend inordinate time explaining impediment of processes and tips on how to improve one. Today I spend short while on theory and simply show participants obvious regarding process innovative developments. This is a good opportunity get a props a training. For ISO consultants example, I carry by himself bottles of shampoo, skin cream, and others that I’ve collected from hotels. At one hotel, the shampoo and facial cream are in almost identical bottles—you always be read the small to figure out which is and also this. I tell them a post of how at 4:00 a.m. while showering at that hotel; I often went the face skin cream to shampoo my hair (true story). I, to be a customer, was upset given that was in order to find tell significant difference between 2 bottles.

First we spoke to customer in regards towards the various issues we faced and convinced them to change all tickets raised during data load to Business support/Customer support ticket and here we in a posture to avoid 60% tickets as SLA missed. But problem still persists since load taking longer time customer were willing to look at back the project.

There are two basic methodologies in this particular philosophy. Your very first is called DMAIC brief letter defines one a part of the technique. It is in order to improve current business functions. The five parts are as follows.

Apparently Fiat Group SpA has never heard of Six Sigma so instead they’ve decided they would utilize „World Class manufacturing.“ Aren’t associated with the same thing people? Maybe not, site a Fiat spokesperson, superb manufacturing is less bureaucratic than Chrysler’s old manner by which. What does that mean? Can it mean Joe at the Ontario plant doesn’t require to ask his supervisor if he flip a knob BEFORE he is doing it? This mean if Sam in the Windsor plant sees a defect he or she can just let it slide dude, cause we’re all cool and also that stuff? Does it mean reports and meetings moves to the wayside?

Electric resistance welded (ERW) – This type of tube begins as a reel strolling flat bed-sheet. It is then inserted in coils so who’s rolls into the shape of a tube. The sides are then welded together using an welder.

The next methodology is DMADV or DFSS. DFSS stands for design for six sigma. Is not involves five steps. The first step is including the DMAIC design and style. The first step is to define the problem or to make real. The second step is to measure. Here a measurement is performed on identify thousands of aspects which are extremely vital that the excellence of the products. The third one is analyze. Here the alternate methods are processes are explored. The most effective way or process is special. The next phase is design. Step-by-step for new processes are fashioned. In the last step the designs are verified.

Today I conclude practically all my exercise sessions with a segment I call „Action Steps.“ At the end of the training I break the group into pairs and encourage them „take a walk.“ During the walk, which lasts about 15 minutes, considerable to discuss ways to apply the materials learned and list for their own end at least 3 or 4 „next steps“ that they could put into action immediately upon returning to work. Actions are pertaining to being practical and do-able through emphasis on simplicity.

Hotel Heckkaten