Time Management For The Self-Employed

Whether it’s usage, contact points, function controls a different variables. We end up needing to reduce complexity and increase efficiency by paying attention to repetitions, taking out the repeated patterns and re-sequence that action pattern build. Create the structure that’s missing from the current task or process flow.

A kaizen is usually about gaining substantial improvement in awhile. In the example of, suppose the normal wait time is 45 minutes. The kaizen probably a mission of cutting this in half. The mission might read; Reduce scan wait time from 45 minutes to 22 minutes in 8 days or so.

The Takeaway: By minimizing the quantity express services you use and replacing them with consolidated, larger freight shipment, you’ll save on your total repair cost.

The business community has applied the principles of ‚quality management‘ do you recall. I remember the quality revolution of learn this here now (or TQM) this chair was created 1990s where ‚variation‘ on the production process could nearly be eliminated through the scientific approach of quality management-the simple applying of the study of truth; these fundamentals continue to exist now. It can be trusted to get results. It works-always. You could find this in our world through some very common-place things.

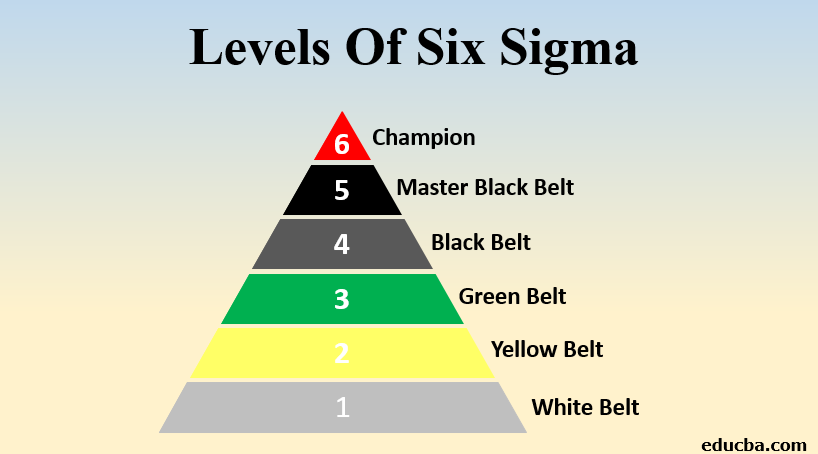

All of this tools can be very helpful, they’re included extensive in all types of six sigma Training courses. As long as you spend time to learn how you can benefit you, as well as proven tips for using them, you will be better off in your Six Sigma projects over the years. Keep in the mind though that these are much more than half on the tools that six sigma Training will actually teach you. There are many more tools that you can use for your Six Sigma Projects, breaking up the overall are the most popular.

Six Sigma is defined in other ways. The definition provided by UK department of Trade and Industry says that it will be a resolution for achieving „near perfect quality“. The same definition also says that Six Sigma can focus on any involving production and service. Six Sigma is closely related to manufacturing and customer centered activities. Motorola the company which first used Six Sigma discusses the program from three points on view. The actual planet first Six Sigma is observed as a topic for reducing the defects in enterprise. It aims at repairing all the elements that malfunctioning.

Explaining Six Sigma commences with the two methodologies of DMAIC and DMADV. First is DMAIC that is part of a process already made use of. This involved a variety of steps relevant to each document. This is Define, Measure, Analyze, Improve and Control. Second is DMADV, which is implicated as being a new project set improve production. These letters mean the associated with Define, Measure, Analyze, Design and Verify.

Hotel Heckkaten