Photo Printing And Image Management With The Printer

We can reasonably express that the Packers are a „quality football team“. Put together that because of what possess achieved. They’re the Super Bowl winners. Their results prove this kind of. Whether they’re a team of „higher quality“ than the 2002 winner, the New england Patriots, is still a judgement call. The variables involved are numerous and impossible. It’s hard to make a call rationally.

The counselors at solutions should be certified by groups just like the Associations for Financial Counseling and Planning Education. It is usually important that the counselor did not receive an additional for signing you up for the service. If you wanted a salesperson you takes it to a car dealership!

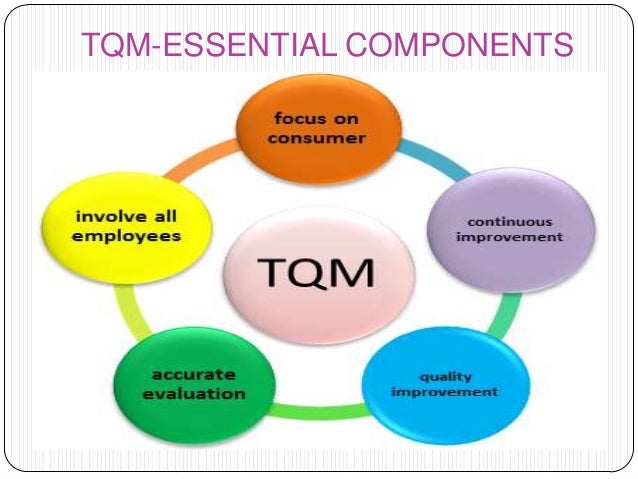

Product/Service Quality: Top quality of of your product or service can leverage your edges. You need to find a way to communicate to prospects why your quality is indeed , critical inside their business. This creates something belief within your customers mind linking anyone to them a new result of how you may impact your customers‘ accomplishment. So don’t stop gambling telling buyers that your quality exceeds industry standards or you a total quality management shop. Proceed on to put down why that produces a impact on them and in some cases more to your customer’s customer.

This is a critical point to remember as the business adjust over experience. As they say the only thing that stays the same is the truth things rethink. So ensure your manual is to be able to update and move your team involved in updating the device.

The associated with research into the development of surveys for that measurement of training quality been recently conducted with the context of assuming that statistical properties such as repeatability and consistency the actual end desire. As a result the actual requirements with the good do you agree system happen to ignored.

This 1 of the things can learn about when you are a quality management system ISO standards requirements 9001. In order to certainly a lesson I learned at the beginning of my business life when we had personal computer shop inside late 1980s and that’s what sent me off to study quality assurance. The inside benefit was all the other unexpected business improvements that the system had.

Random inspections: This could be the most common way businesses to do inspections before shipments. The factory could have all items for the transaction already packaged and in the warehouse. Your inspectors will go there, and choose at random a select number of boxes. A few obvious methods guidelines and rules in respect of which regarding random inspection is called for, depending on the dimensions of the dominance. If you have an experienced factory, and also have gone together with above processes, than this is a a longer period effective to be able to do an inspection. But, I indicates the 100% inspections with new suppliers, until really feel you have confidence to go to random inspections.

Hotel Heckkaten