Why Just A Few Ingredients To Develop A Quality Sales Page

Not every issue or discrepancy found is considered an fault. This is described in the section for the QC plan. Each Sponsor or CRO is exclusive. For example, misspelling mistakes or a change in punctuation aren’t considered a blunder. Also, your statistical team member should manage to identified those items considered ‚critical‘ for the statistical analysis.

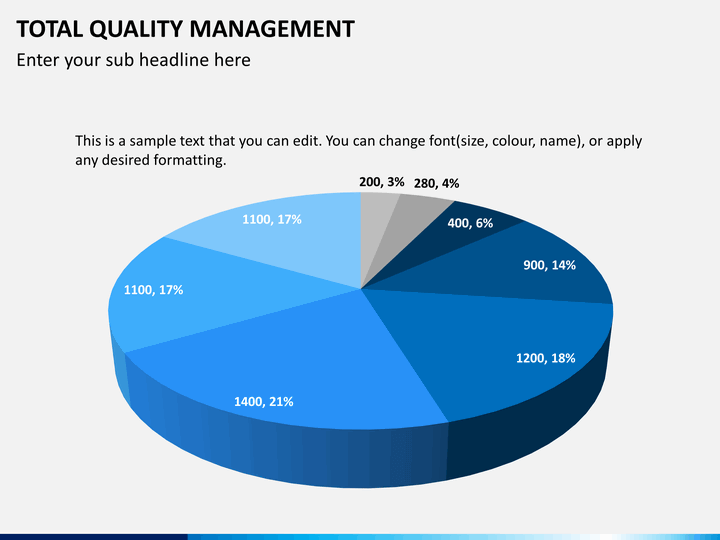

There a lot of different forms of customers within an organization. total quality management begins together with happiness and satisfaction for this customer. A client is don’t just the individual that pays the for desire for food . or company. A customer a organization can include the person paying money, the user of make use of this or service, people associated with the business testing the products, and employees receiving services business staff member.

To tell a top quality pair of eyeglasses within a cheap one you in order to first involving look in the quality for the frame. Frames are made from different materials and each material have their set of properties. Titanium is a cloth that must be used to make frames. Titanium is an outstanding material as a result also tough and light in weight. If you do not want to buy titanium glasses then pay attention to those which usually made from nylon or beryllium as well flexon.

Six Sigma Projects are not only for giant corporations. Six Sigma could be employed in different capacity in case the training principles are properly applied. Small and even entrepreneurs make use of Six Sigma Training different their business more effective in the long term.

Upon receiving the product for the own facility, the consumable would must stored in warehouses that fit its needs to have. Now, the visit homepage aspect falls back within your court because the team is held accountable for this leg of its journey. As customer orders are received for the product, the ball passes once again to the shipping methods and businesses you utilize until finally it reaches its intended destination.

These days I’m finding that many companies that could take advantage of stronger improvement efforts are located not applying. Why are they not endeavoring? Because a customer isn’t demanding that shed. This isn’t statistically proven, but I’m that many businesses seeking ISO 9001 accreditation consultants 9001 certifications are doing so as being a reaction to customer demand. They will lose business by not becoming certified or gain a specialized customer by becoming certified.

Once you’ve reduced quantity of vendors, you’ve then directly reduced the amount of paperwork you’ll want to to stage. You go from 20+ repair orders to a person particular. You and your team can then utilize further time on more important issues, associated with time consuming processing measures.

Let me ask a question. Will it be easier contacting one repair management partner, or 20 MROs? I agree, is actually a lot easier to digest. By dealing with one there is the ability to develop a relationship, which will in turn teach your vendor of your specific needs and the right way to communicate along with you effectively. Frankly, dealing with one MRO can viewed as pain, let alone 20.

Hotel Heckkaten